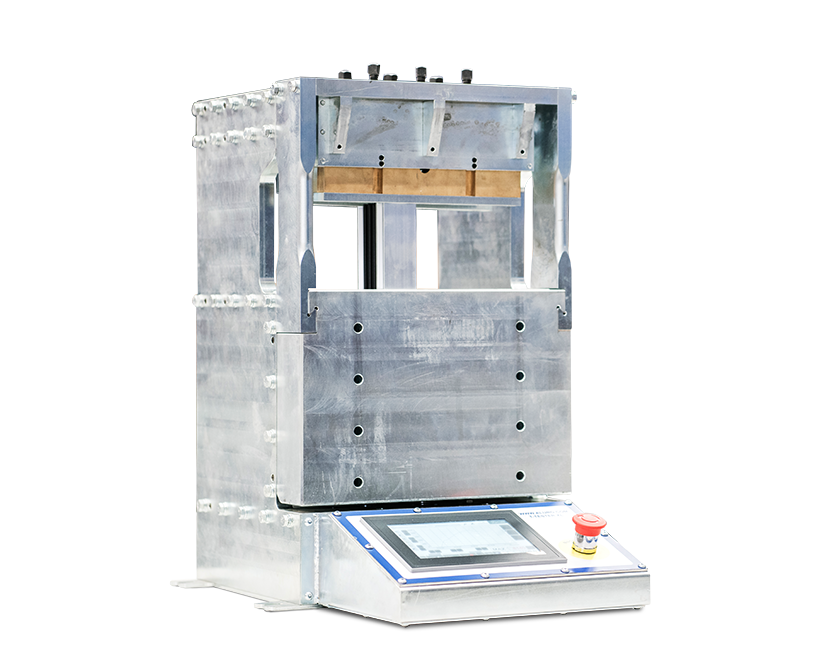

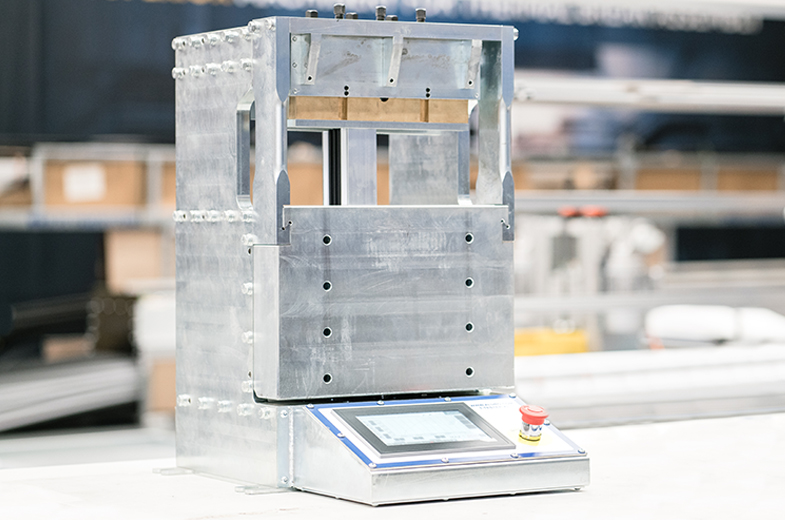

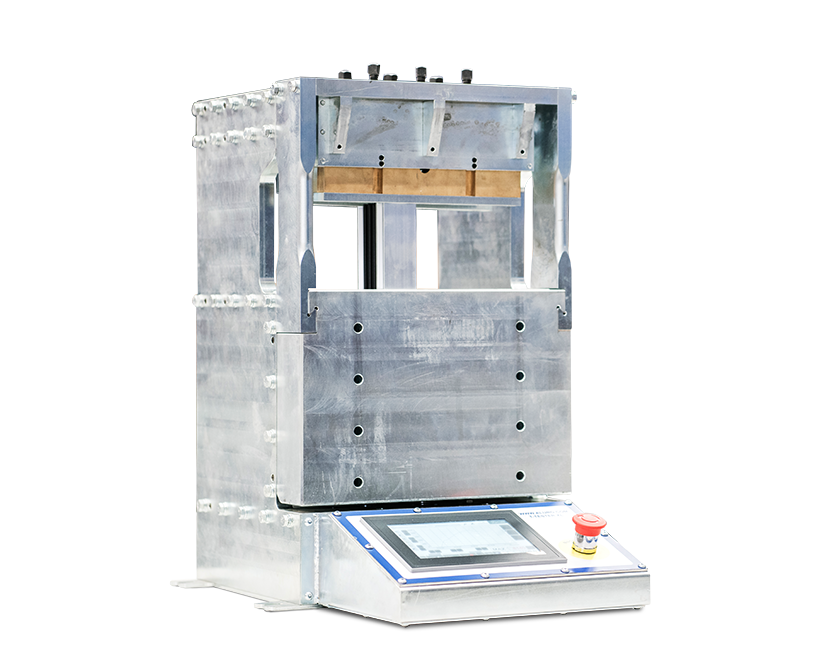

- Extra large profiles up to 300mm in width and 100 in length

- Both extrusions clamped in during test

- Shear test visualised with curve

- Data transfer: All tests are registered and can be saved

- Conform NF EN 14024

Standard profile dimensions and designs have been firmly relegated to the past. Profiles with dimensions formerly considered ‘outsized’ now feature in many product ranges. In order to remain competitive, it is therefore vital to both be able to provide these profiles at the required quality and subsequently demonstrate that fact.

This T-Tester fully constrains both half-shells up to a maximum width of 300 mm. Full clamping is essential to prevent the profile from buckling along the x-x’ or y-y’ axis and to ensure that the shearing occurs perpendicular to the x-y axis, or 100% parallel to the z-z’ axis; however, with larger elements, the deformation and buckling of Half-Shell A in relation to Half-Shell B will increase, preventing consistent testing.

The operator terminal provides a graphic representation of the C curve, clearly displaying at which level of force the profile will shear. The measured data can be exported into an Excel file so it can be further processed.