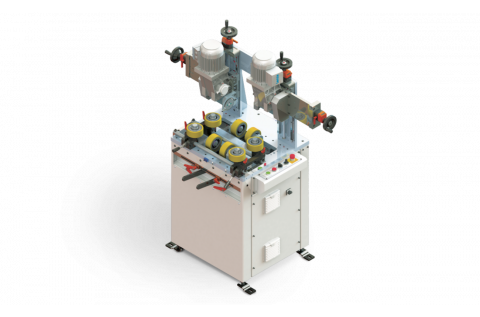

- Stand-alone machine, with which the strips are locked and the assembly is completed

- Easy integration into existing production lines

- 2x2 extra support rolls adjustable for higher profiles

After the knurling and the assembly, the final step is the rolling (or crimping). During this final step, the aluminium extrusions and the thermal strip are fastened to prevent any later shearing.