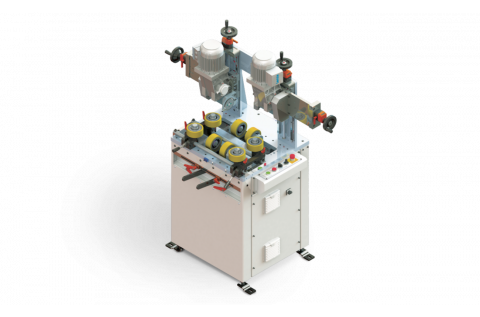

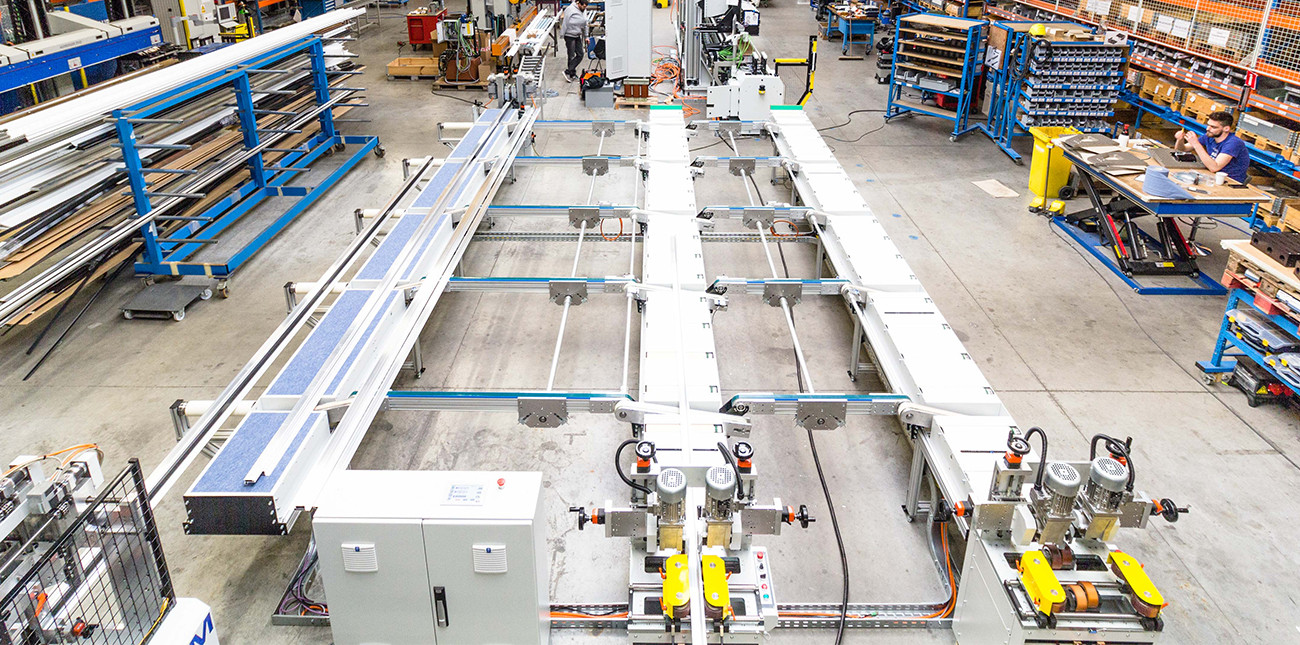

The Aluro BTM series is exceptionally reliable. These solid, well-designed machines guarantee low costs in tooling and maintenance, quick set-up times, high-quality results, and easy-to-operate controls.

To assemble an aluminium profile that includes a thermal break, the three different steps of the thermal insulation process must be completed:

- The knurling of the profiles

- The introduction of the insulation strips

- The rolling (or crimping)

Aluro offers a separate BTM machine for each of these steps, ensuring that they can easily be added to your current production line.

Every BTM machine can be deployed separately in your existing production line. Alternatively, you can set these three machines up as a single operating configuration, making it possible to complete the entire thermal break assembly process quickly and efficiently.